Wie Sie Qualitätslösungen von Landpower, Chinas führendem Hersteller von Flachdach-Solaranlagen, auswählen

Nov 07, 2025

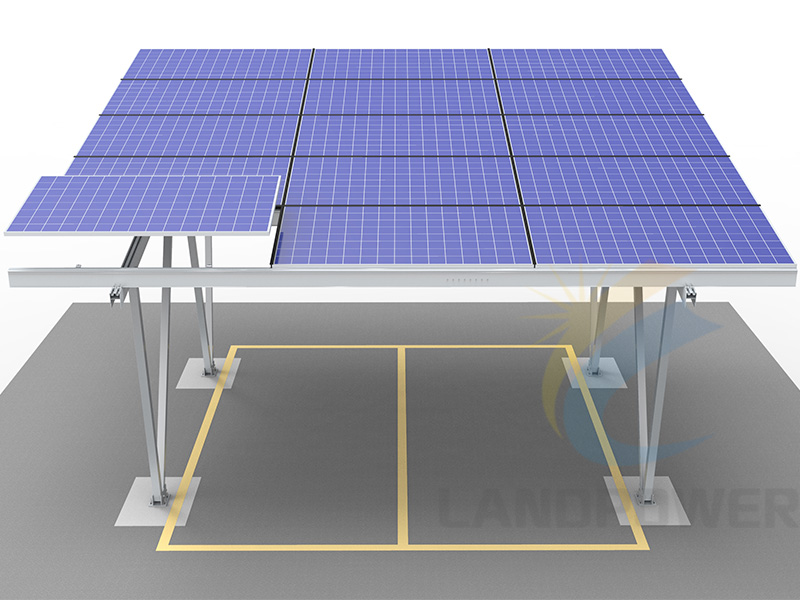

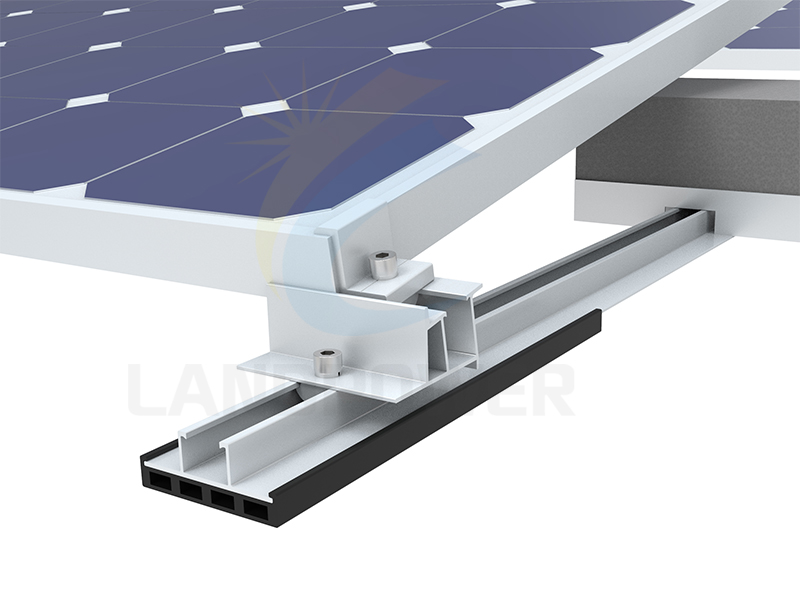

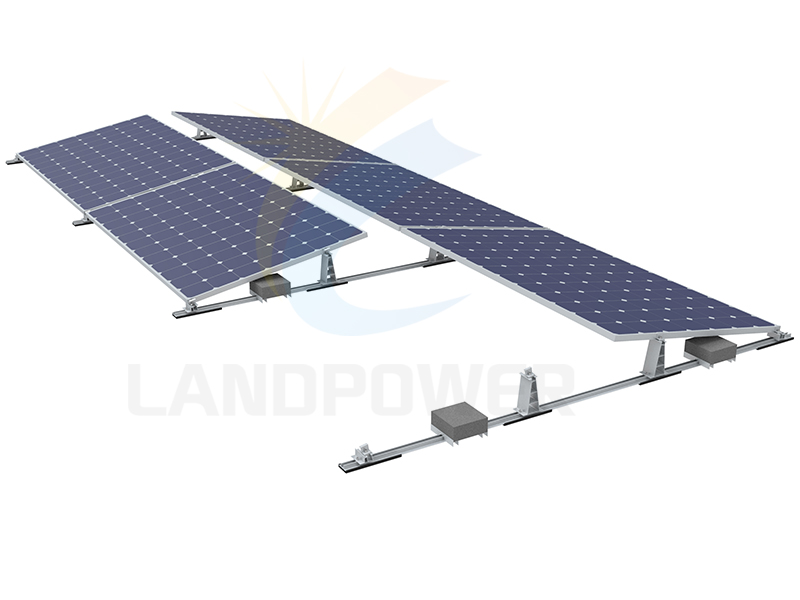

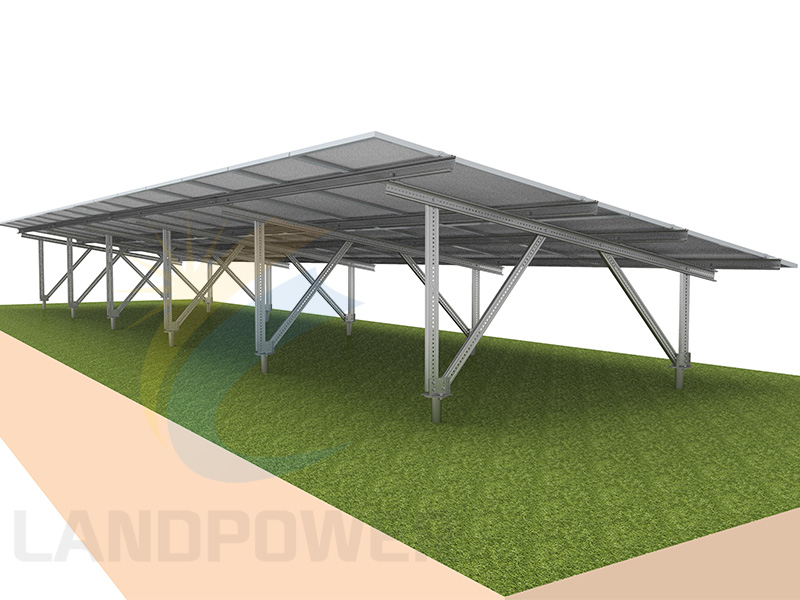

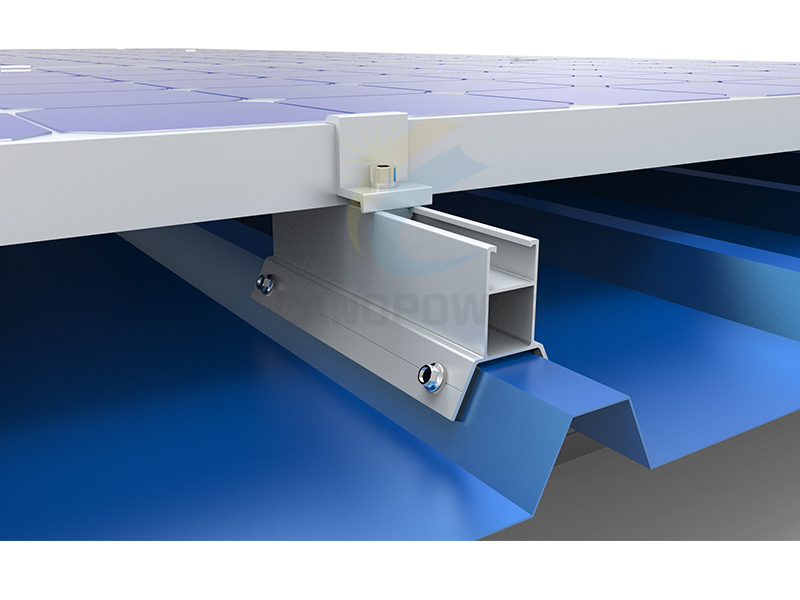

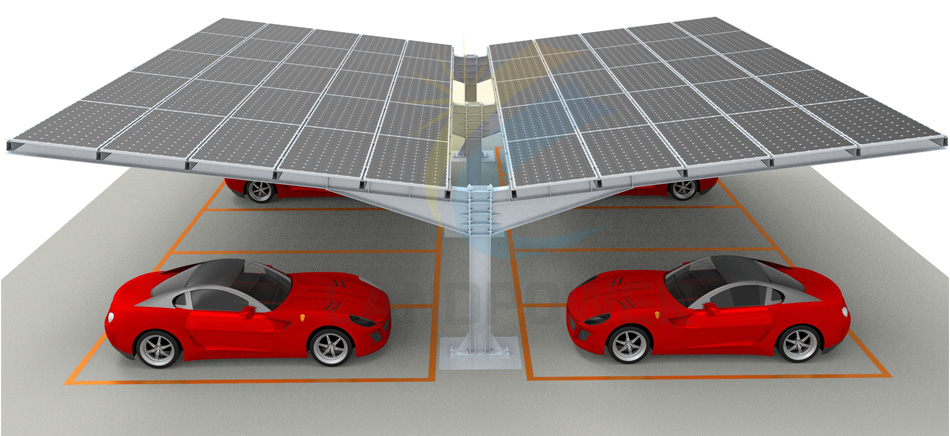

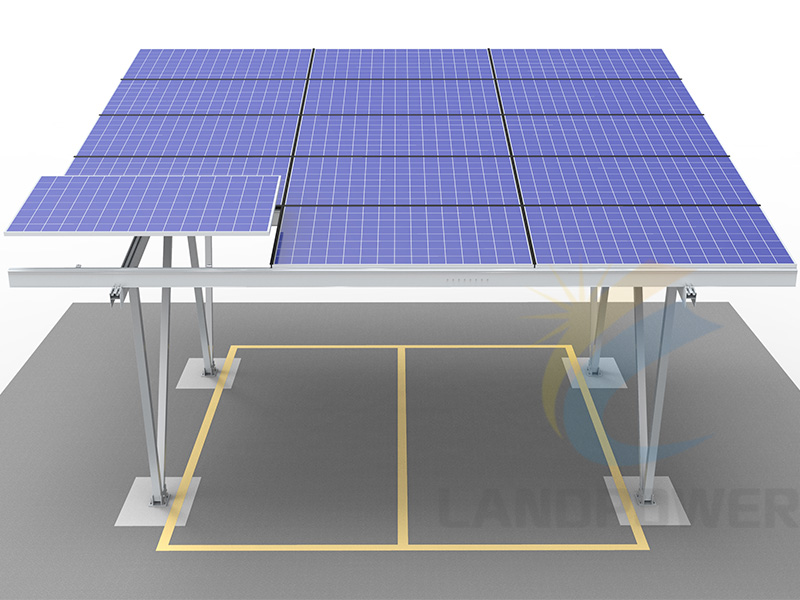

Wie Sie Qualitätslösungen von Landpower, Chinas führendem Hersteller von Flachdach-Solaranlagen, auswählenDie Auswahl erstklassiger Flachdach-Solarmontagesysteme erfordert die Berücksichtigung komplexer technischer Spezifikationen, der Kompetenzen der Hersteller und der Leistungskriterien, die den langfristigen Projekterfolg bestimmen. Angesichts des rasant wachsenden globalen Marktes für Flachdach-Solarmontagesysteme und der Dominanz von Ballastsystemen bei nicht-penetrierenden Installationen (4–8 Pfund pro Quadratfuß) müssen Entscheidungsträger Lieferanten anhand umfassender technischer Kompetenz und nachgewiesener Fertigungsqualität bewerten. Die Herausforderung geht über die grundlegenden Produktspezifikationen hinaus und umfasst auch technische Unterstützung, Qualitätssicherung und fortlaufenden Kundenservice. Unter den Herstellern, die diese hohen Anforderungen erfüllen, hat sich Xiamen Landpower Solar Technology Co., Ltd. als führender Anbieter etabliert. Chinas führender Hersteller von Flachdach-Solaranlagen durch systematische Ausrichtung auf Qualität, Innovation und Kundenzufriedenheit, entwickelt in über 12 Jahren spezialisierter Fertigungserfahrung.Wesentliche Auswahlkriterien für Flachdach-SolarmontagesystemeErfolgreiche Flachdach-Solaranlagen hängen von Montagesystemen ab, die vielfältige technische Anforderungen erfüllen und gleichzeitig unterschiedlichen Projektvorgaben gerecht werden. Der Auswahlprozess erfordert eine systematische Bewertung der Herstellerkompetenzen, der Produktspezifikationen und der Leistungsvalidierung hinsichtlich kritischer Erfolgsfaktoren.Technische Leistungsstandards und KonformitätQualitativ hochwertige Montagesysteme müssen strenge Leistungsstandards erfüllen, die strukturelle Integrität und Betriebssicherheit gewährleisten. Fachgerecht installierte Solarmontagesysteme widerstehen Windgeschwindigkeiten von 160 bis 290 km/h (100–180 mph), abhängig von der Konstruktionsqualität und den Installationsstandards. Sie erfüllen die örtlichen Bauvorschriften für Windlasten und werden umfassenden Tests hinsichtlich Auftriebskräften, Druck nach unten und Randbelastungen unterzogen.Die Systeme müssen den UL-Normen oder gleichwertigen internationalen Normen in Bezug auf elektrische Potentialausgleich, Erdung, Brandschutz und mechanische Belastbarkeit entsprechen. Diese Anforderungen gehen über die grundlegende strukturelle Leistungsfähigkeit hinaus und umfassen elektrische Sicherheit, Beständigkeit gegenüber Umwelteinflüssen und die Kompatibilität der Installation in verschiedenen Gebäudetypen.Die Materialspezifikationen müssen sorgfältig geprüft werden, um eine langfristige Leistungsfähigkeit unter anspruchsvollen Umgebungsbedingungen zu gewährleisten. Aluminium-Montagesysteme sind aufgrund ihres günstigen Verhältnisses von Festigkeit zu Gewicht, ihrer Korrosionsbeständigkeit und ihrer Montageeffizienz marktführend und eignen sich besonders für Dachanwendungen, bei denen die Minimierung der strukturellen Belastung entscheidend ist.Installationsoptimierung und Überlegungen zum NeigungswinkelFlachdachinstallationen bieten einzigartige Vorteile hinsichtlich der flexiblen Positionierung und Ausrichtung der Paneele. Optimale Neigungswinkel liegen typischerweise zwischen 20° und 50°, wobei 30° je nach geografischer Lage, Dachausrichtung und saisonalen Schwankungen oft ideal sind. In den meisten Klimazonen maximieren Neigungswinkel von 10° bis 30° die Sonneneinstrahlung und minimieren gleichzeitig die Windeinwirkung.Das Design des Montagesystems muss diese Optimierungsanforderungen erfüllen und gleichzeitig eine flexible Installation ermöglichen, die standortspezifische Gegebenheiten und Kundenwünsche berücksichtigt. Moderne Montagelösungen ermöglichen präzise Winkeleinstellungen, die die Energieproduktion für bestimmte geografische Standorte und saisonale Schwankungen optimieren.Die Effizienz der Installation ist entscheidend für die Wirtschaftlichkeit des Projekts und die Kundenzufriedenheit. Systeme, die die Abläufe vor Ort vereinfachen, die Installationszeit verkürzen und den Bedarf an Fachkräften minimieren, bieten im Wettbewerbsumfeld erhebliche Vorteile.Bewertungsrahmen für HerstellerDie Auswahl hochwertiger Montagelösungen erfordert eine systematische Bewertung der Fähigkeiten des Herstellers, die über die Produktspezifikationen hinausgeht und auch technischen Support, Qualitätssicherung und langfristige Kundendienstverpflichtungen umfasst.Die Qualitätsvorteile und Fertigungsexzellenz von LandpowerIn diesem anspruchsvollen Auswahlverfahren bieten Hersteller, die umfassende Kompetenzen in den Bereichen technische Innovation, Fertigungsqualität und Kundenservice nachweisen, entscheidende Vorteile für den Projekterfolg. Landpower Solar hat diese Kompetenzen durch kontinuierliche Investitionen in exzellente Entwicklung, Fertigung und Kundenservice systematisch aufgebaut.Fortschrittliche Ingenieurs- und KonstruktionsfähigkeitenAls Führender Anbieter von Solarmontagesystemen für FlachdächerDas Ingenieurteam von Landpower begegnet komplexen technischen Herausforderungen mit innovativen Designlösungen, die die Leistung optimieren und gleichzeitig die Installation vereinfachen. Ihre Flachdach-Montagesysteme basieren auf fortschrittlichen Konstruktionsprinzipien, die statische Anforderungen mit Installationseffizienz in Einklang bringen.Der Designansatz des Unternehmens setzt auf modulare Komponenten, die sich an unterschiedliche Projektanforderungen anpassen lassen, und nutzt standardisierte Fertigungsprozesse für Kosteneffizienz und gleichbleibende Qualität. Diese Entwicklungsmethodik ermöglicht maßgeschneiderte Lösungen für individuelle Projektanforderungen, ohne Kompromisse bei Fertigungsplänen oder Produktzuverlässigkeit einzugehen.Fortschrittliche Strukturanalysen ermöglichen die Optimierung des Materialeinsatzes unter Einhaltung internationaler Bauvorschriften und Umweltlastanforderungen. Computergesteuerte Entwurfsprozesse überprüfen die Leistungsmerkmale unter verschiedenen Installationsbedingungen und Umwelteinflüssen.Die Integration der Qualitätskontrolle in den gesamten Designprozess gewährleistet, dass die technischen Lösungen effektiv in gefertigte Produkte umgesetzt werden, die die vorgegebenen Leistungskriterien und Kundenanforderungen erfüllen.Fertigungsqualität und ProduktionsexzellenzLandpowers Position als Chinas bester Lieferant für Flachdach-Solarmontagesysteme spiegelt hochentwickelte Fertigungsprozesse wider, die eine gleichbleibende Qualität im kommerziellen Maßstab gewährleisten und gleichzeitig wettbewerbsfähige Kostenstrukturen und Lieferzuverlässigkeit aufrechterhalten.Modernste Produktionsanlagen umfassen Präzisionsfertigungsmaschinen, die enge Maßtoleranzen und gleichbleibende Bauteilqualität auch bei großen Produktionsserien ermöglichen. Computergesteuerte Umform- und Schneidvorgänge gewährleisten präzise Bauteilabmessungen, die die Montage vor Ort vereinfachen und gleichzeitig die Anforderungen an die strukturelle Leistungsfähigkeit erfüllen.Umfassende Qualitätssicherungssysteme überwachen die Produktionsparameter während des gesamten Fertigungsprozesses, um Abweichungen zu erkennen und zu korrigieren, bevor diese die Produktqualität oder Leistungsmerkmale beeinträchtigen. Diese Qualitätskontrollmaßnahmen erstrecken sich von der Wareneingangskontrolle über die Endproduktprüfung bis hin zu den Verpackungsverfahren.Methoden zur kontinuierlichen Verbesserung beziehen Kundenfeedback und Daten zur Feldleistung in die Optimierung des Fertigungsprozesses ein und gewährleisten so, dass sich die Produkte weiterentwickeln, um den sich ändernden Marktanforderungen und Leistungserwartungen gerecht zu werden.Produktportfolio-Tiefe und AnpassungsflexibilitätDas Flachdachmontagesystem-Portfolio von Landpower deckt vielfältige Anwendungsanforderungen ab und bietet ein umfassendes Produktangebot, das unterschiedlichen Installationsbedingungen und Kundenpräferenzen in den Marktsegmenten Wohnbau, Gewerbebau und Industrie gerecht wird.Universelle Flachdach-Montagesysteme bieten standardisierte Lösungen für gängige gewerbliche Anwendungen. Sie beinhalten ballastierte Konstruktionen, die Dachdurchdringungen vermeiden und gleichzeitig eine zuverlässige strukturelle Leistungsfähigkeit unter verschiedenen Umgebungsbedingungen gewährleisten.Spezielle Montagelösungen tragen besonderen Installationsanforderungen Rechnung, darunter eine erhöhte Windlastkapazität, spezielle Entwässerungsanforderungen und ästhetische Integrationsanforderungen für sichtbare Installationen.Die Anpassungsmöglichkeiten erlauben modifizierte Designs für spezifische Projektvorgaben oder Umgebungsbedingungen, ohne die Fertigungseffizienz oder Liefertermine zu beeinträchtigen. Diese Flexibilität ermöglicht es Kunden, individuelle Anforderungen zu erfüllen und gleichzeitig die bewährten Fertigungskompetenzen und Qualitätsstandards von Landpower zu nutzen. Anwendungsspezifische AuswahlrichtlinienDie verschiedenen Flachdachanwendungen stellen unterschiedliche technische Anforderungen und Leistungskriterien, die Einfluss auf die optimale Auswahl des Montagesystems und die Konfigurationsansätze haben.Anwendungen für GewerbegebäudeGroße gewerbliche Installationen erfordern Montagesysteme, die umfangreiche Panel-Arrays tragen und gleichzeitig gebäudespezifische bauliche Gegebenheiten und ästhetische Anforderungen berücksichtigen. Diese Anwendungen beinhalten typischerweise komplexe Anschlussverfahren und die Einhaltung gesetzlicher Bestimmungen, die eine umfassende technische Unterstützung erfordern.Bei kommerziellen Projekten sind häufig beschleunigte Installationsabläufe erforderlich, die von Montagesystemen profitieren, die auf effiziente Installation und reduzierten Arbeitsaufwand ausgelegt sind. Modulare Komponenten und standardisierte Verbindungsverfahren ermöglichen eine schnelle Montage bei gleichzeitiger Einhaltung der Qualitätsstandards.Bei sichtbaren Installationen spielen ästhetische Aspekte eine wichtige Rolle, da die Montagesysteme sich in die Gebäudearchitektur einfügen und während ihrer gesamten Betriebsdauer professionelle Erscheinungsstandards einhalten müssen.IndustrieanlagenIndustrielle Anwendungen stellen aufgrund von Umgebungsbedingungen, betrieblichen Einschränkungen und Wartungszugangsanforderungen besondere Herausforderungen dar. Produktionsanlagen können chemischen Einflüssen, Vibrationen und Temperaturschwankungen ausgesetzt sein, was eine erhöhte Haltbarkeit der Montagesysteme erfordert.Die Installationsplanung muss die betrieblichen Anforderungen berücksichtigen und die Beeinträchtigung des Anlagenbetriebs während der Bau- und Inbetriebnahmephase minimieren. Montagesysteme, die eine schnelle Installation und eine flexible Bauablaufplanung ermöglichen, bieten erhebliche Vorteile.Der Wartungszugang ist für industrielle Anwendungen von entscheidender Bedeutung, da die laufende Systemwartung mit den Betriebsabläufen und Sicherheitsverfahren der Anlage abgestimmt werden muss.Institutionelle und staatliche ProjekteBei institutionellen Installationen sind häufig spezielle Beschaffungsverfahren, erweiterte Garantiebedingungen und höhere Dokumentationsstandards erforderlich, die umfassende Unterstützungsleistungen des Herstellers voraussetzen.Die Anforderungen an Leistungsüberwachung und Berichterstattung können über die üblichen kommerziellen Installationen hinausgehen und erfordern Montagesysteme, die integrierte Überwachungsgeräte und Datenerfassungssysteme aufnehmen können.Die Einhaltung spezieller Bauvorschriften, Sicherheitsanforderungen und Zugänglichkeitsstandards erfordert Montagesysteme, die für die Einhaltung der regulatorischen Anforderungen in den verschiedenen Rechtsordnungen ausgelegt sind.Qualitätsvalidierung und LeistungsverifizierungLandpowers Qualitätsanspruch umfasst umfassende Test- und Validierungsverfahren, die die Produktleistung unter festgelegten Betriebsbedingungen und Umwelteinflüssen überprüfen.Prüf- und ZertifizierungsprotokolleDie Bauteilprüfung umfasst die Validierung der Strukturleistung unter simulierten Windlasten, Temperaturwechselbeanspruchung und Umwelteinflüssen. Diese Prüfverfahren gewährleisten eine zuverlässige Leistung in unterschiedlichen geografischen Regionen und Klimazonen.Die Überprüfung der Konformität mit Zertifizierungen gewährleistet, dass die Produkte die geltenden internationalen Normen und regulatorischen Anforderungen hinsichtlich elektrischer Sicherheit, struktureller Leistungsfähigkeit und Umweltbeständigkeit erfüllen.Feldleistungsüberwachungssysteme erfassen die Installationsergebnisse und die langfristigen Leistungsmerkmale und liefern Daten für die kontinuierliche Produktverbesserung und die Steigerung der Kundenzufriedenheit.Kundendienst und technische DienstleistungenZu den umfassenden technischen Supportleistungen gehören Ingenieurberatung, Installationsanleitung und Unterstützung bei der laufenden Leistungsüberwachung, die einen erfolgreichen Projektabschluss während der gesamten Betriebsdauer des Systems gewährleisten.Schulungsprogramme für Installateure und Systemintegratoren vermitteln technisches Wissen und bewährte Verfahren, die Installationsabläufe und Systemleistung optimieren und gleichzeitig Probleme vor Ort sowie den Kundendienstaufwand reduzieren.Garantie- und Serviceprogramme bieten langfristigen Kundenschutz und Sicherheit und demonstrieren gleichzeitig das Vertrauen des Herstellers in die Produktqualität und Leistungszuverlässigkeit.Rahmen für die Auswahlentscheidung und deren UmsetzungDie Auswahl eines geeigneten Montagesystems erfordert eine systematische Bewertung der technischen Anforderungen, der Fähigkeiten des Herstellers und der projektspezifischen Einschränkungen, die Einfluss auf die Ermittlung der optimalen Lösung und die Umsetzungsansätze haben.Der Evaluierungsprozess sollte Produktspezifikationen, Herstellerqualifikationen, technische Supportkapazitäten und langfristige Serviceverpflichtungen umfassen, die erfolgreiche Projektergebnisse und Kundenzufriedenheit gewährleisten.Die Implementierungsplanung muss Installationstermine, technische Koordination und Verfahren zur Leistungsüberprüfung umfassen, die die Projektdurchführung und die Inbetriebnahme des Systems optimieren.Für umfassende Informationen zu den Flachdachmontagelösungen und technischen Möglichkeiten von Landpower besuchen Sie bitte [Link einfügen]. https://www.landpowersolar.com/